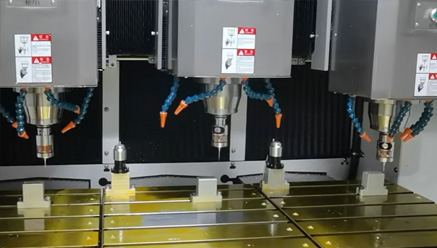

To meet the demand for large-scale production of automotive components, Heidena products are used for automated online detection of engine cylinder blocks/holes, transmission gears, new energy battery boxes, etc., to achieve real-time monitoring of tool wear, and more

Aviation components have strict requirements for accuracy and reliability, and the Heidener high-precision probe achieves the contour of turbine blade surfaces, engine casing positioning holes, and landing gear structural components

The processing quality of engineering machinery parts is related to the safety and service life of engineering machinery, as well as the comprehensive cost control of engineering machinery using enterprises. The application of Heidener machine tool probes can improve the machining quality of engineering machinery parts

The curved surface of the mold cavity and the mating surface of the insert require a high degree of fit. Heidena products compare CAD models in real-time to achieve iterative mold repair and wear monitoring of injection molds and die-casting molds, shortening the mold debugging cycle by 50% and improving its lifespan

In response to the micro level precision requirements of biocompatible implants such as artificial joints and dental implants, the Heidena laser tool setter achieves non-destructive measurement of titanium alloy/ceramic workpiece surfaces through non-contact optical scanning, avoiding surface damage caused by traditional contact force measurement

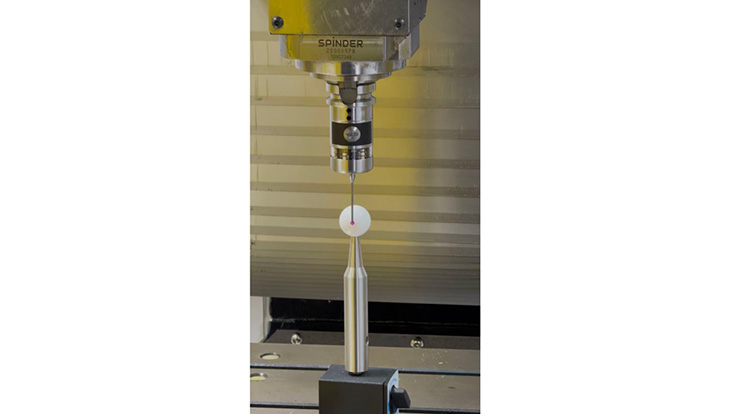

CNC online measurement technology is an important techn···

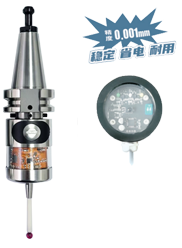

High precision 3D machine tool probe is an advanced mea···

In order to improve processing efficiency, the applicat···