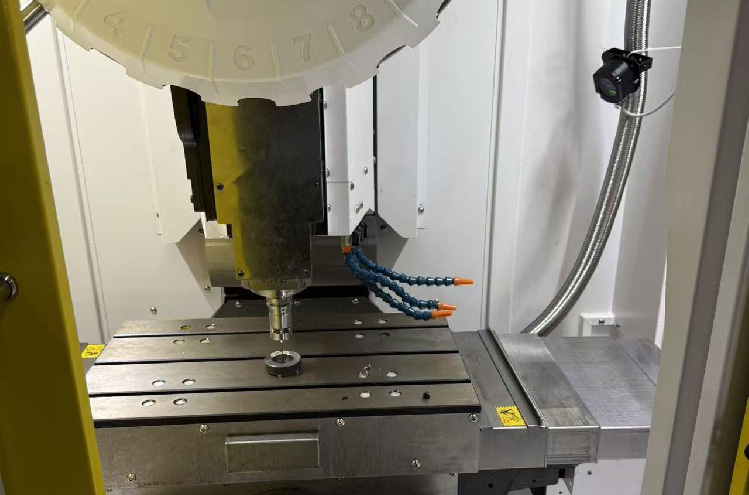

CNC online measurement technology is an important technological advancement in the modern manufacturing industry. It combines computer numerical control (CNC) technology with advanced measurement techniques to achieve real-time and high-precision measurement of workpiece size and shape during the machining process. CNC online measurement technology not only improves production efficiency, but also ensures the stability and consistency of product quality.

Technical Features

Real time performance: CNC online measurement technology can obtain real-time size and shape data of workpieces during the machining process, providing real-time feedback for machining control.

High precision: Advanced measurement sensors and algorithms are used to ensure the accuracy and reliability of measurement results.

Automation: Integrated with CNC machine tools to achieve automation and intelligence in the measurement process.

Data Traceability: Recording and analyzing measurement data to achieve traceability in product quality control.

Application scenarios

CNC online measurement technology is widely used in manufacturing industries such as automobiles, aerospace, molds, and precision instruments. It is particularly suitable for complex workpieces and high-precision machining scenarios, such as high-precision molds, engine components, etc.

System Composition

The CNC online measurement system mainly consists of the following parts:

Measurement sensor: a device used to obtain data on the size and shape of workpieces, such as laser rangefinders, contact gauges, etc.

Data processing unit: a device responsible for receiving and processing measurement data, and outputting measurement results, usually integrated with CNC machine control systems.

Measurement software: software used to control the measurement process, analyze measurement data, and generate measurement reports.

Technical advantage

Improve production efficiency: Real time measurement reduces downtime for testing and debugging, improving production efficiency.

Ensure product quality: High precision measurement ensures the accuracy and stability of product dimensions, reducing the rate of defective products.

Cost reduction: Reduced the cost of manual inspection and debugging, while also lowering the scrap and rework rates.

Optimizing the machining process: Through real-time feedback, machining parameters can be adjusted in a timely manner to optimize the machining process.