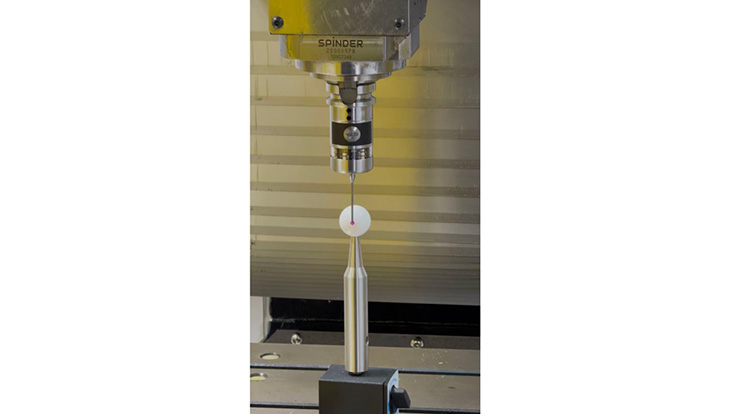

High precision 3D machine tool probe is an advanced measuring device specifically designed for 3D measurement on high-precision machining centers and multi axis machine tools. It can perform high-precision 3D spatial measurement during the machining process, achieving precise machining and quality control of complex shaped workpieces. This technology greatly improves the machining accuracy and efficiency of complex parts, and is an indispensable tool for modern precision manufacturing. Here is a detailed introduction by Heidener on high-precision 3D machine tool probes:

1. Definition and Function

High precision 3D machine tool probe is a 3D measuring device installed on high-end machining centers or multi axis machine tools, with main functions including:

-Three dimensional positioning and alignment of complex workpieces

-Real time 3D dimension measurement during processing

-Measurement of contours and shapes of complex surfaces

-Workpiece attitude correction in multi axis machining

-High precision tool setting and compensation

2. Working principle

High precision 3D machine tool probes typically use multi axis triggering mechanisms or optical sensing technology. It can measure in the X, Y, and Z directions, and some also have the ability to rotate, which can measure complex three-dimensional shapes.

3. Main types

-Triggered 3D probe: Obtaining three-dimensional coordinates through physical contact

-Scanning 3D probe: capable of continuously collecting surface point cloud data

-Laser 3D probe: using laser technology for non-contact measurement

-Multi sensor 3D probe: combining multiple measurement techniques such as triggering, scanning, and vision

4. Main advantages

-Ultra high precision: measurement accuracy up to sub micron level

-Omnidirectional measurement: capable of measuring features in all directions

-Strong adaptability: suitable for complex shapes and multi axis machining

-Improve efficiency: reduce the transfer of workpieces between machine tools and measuring equipment

-Real time compensation: able to compensate for machining errors and thermal deformation in a timely manner

5. Application Fields

-Aerospace parts processing

-Precision Medical Device Manufacturing

-Optical component processing

-Precision mold manufacturing

-High precision machining of automotive components

6. Key parameters

-Measurement accuracy: typically up to 0.5 microns or higher

-Repeatability accuracy: consistency of multiple measurements

-Measurement force: the force of contact with the workpiece (for trigger type probes)

-Measurement range: maximum measurable working range

-Scanning speed: Point cloud acquisition speed for scanning probes

7. Choose factors to consider

-Machine tool type and accuracy level

-The complexity and precision requirements for processing workpieces

-Measurement speed and efficiency requirements

-Integration capability with CAD/CAM systems

-Environmental factors (temperature fluctuations, vibrations, etc.)

-Return on investment and long-term usage cost

8. Precautions for use

-Accurate installation and calibration to ensure complete alignment with the machine coordinate system

-Regular inspection and maintenance to maintain high precision performance

-Consider the impact of temperature on measurement and use temperature compensation if necessary

-Reasonably plan measurement strategies and optimize measurement paths

-Pay attention to avoiding interference between the measuring head, workpiece, and fixture

9. Maintenance and Calibration

-Regularly perform precision calibration using high-precision calibration balls or standard parts

-Clean the probe system, especially for measuring contact points or optical windows

-Check and replace worn measuring pins or other vulnerable components

-Update probe software and compensation database

-Regularly conduct system diagnostics to ensure that all functions are functioning properly

10. Development Trends

-Higher precision: moving towards nanometer level measurement accuracy

-Intelligence: Integrating artificial intelligence algorithms to achieve adaptive measurement

-Multi functional integration: combining multiple measurement technologies into one

-High speed measurement: Improve scanning and data processing speed

-Thermal stability: Improve temperature compensation technology to reduce the impact of thermal deformation

As an important component of advanced manufacturing technology, high-precision 3D machine tool probes are driving the development of precision machining towards higher precision, efficiency, and intelligence. It not only improves the machining accuracy and efficiency of complex parts, but also provides key support for achieving intelligent manufacturing and flexible production. With the continuous advancement of measurement technology, data processing capabilities, and artificial intelligence, high-precision 3D machine tool probes will play an important role in a wider range of high-end manufacturing applications and become a key tool to enhance the core competitiveness of the manufacturing industry.

When selecting and using high-precision 3D machine tool probes, it is necessary to comprehensively consider processing requirements, environmental factors, and economic benefits, choose appropriate types and specifications, and carry out daily maintenance and precise calibration to fully leverage their advantages and achieve efficient and high-quality precision machining. With the deepening development of manufacturing towards intelligence and digitization, high-precision 3D machine tool probes will play an increasingly important role in improving production efficiency, ensuring product quality, and achieving intelligent manufacturing, especially in cutting-edge manufacturing fields such as aerospace, medical equipment, and optics that require extremely high precision.